The fit of a shoe depends on the design, shape and volume of the Shoe Last.The shoe last must represent the anatomical information of the foot, at the same time giving the finished shoe a pleasing and fashionable appearance. Studies show over 90% of people have different sized feet and the individual foot has an infinite variation of morphology despite this lasts are made to match as a pair. The concept of a perfect fit is not a reality.

The shoe is expected to wear well, feel well, keep its shape with wear, retain its style character, tread properly, allow for reasonable foot freedom, maintain both foot and shoe balance, remain structurally intact

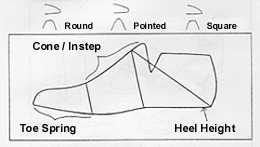

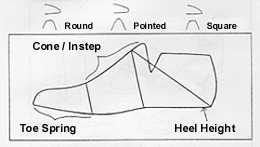

Chart showing the main parts of a " Shoe Last "

Chart showing the main parts of a " Shoe Last " Shoe last is the form that shoemakers use in shoe molding and it is the anatomical “copy” of our feet.Shoe last comes in different forms, shapes and are made from different materials. Shoe lasts are the basis of making quality shoes. Perfectly fitting shoes can only be made with the use of a perfect last. These days Plastic lasts are very common due to ease in making and non availability of quality wood.The process is very similar to wooden lasts but the material treatment is different.

We apply our footwear design on the shoe lasts, make our pattern with the shoe last, Do lasting of uppers on the shoe last and also make shoe sole and leather heels on the shoe last.

There are 3 materials shoe lass are made from;

1. Wood 2. Plastic 3. Aluminium

Wooden Shoe Last

Last is the “foot copy” mold upon which a shoe is constructed. That is why shoe lasts that are made of wood is usually used in bespoke making of shoes.Shoemaker or a lasts maker takes the persons feet measurements and creates wooden lasts that are perfectly fits that person. Shoe last making is a craft on its on with a long history and in the traditional way of last making is to shape a last from a hard type of wood (usually maple) with a last makers knife.

Bespoke making of shoes is pretty expensive and making of perfect shoes always begins from bespoke wooden lasts.

Plastic Last

Plastic lasts are the most used in making of shoes. Maybe this is not the best material for molding shoes and it is defiantly adds to our pollution problem, but it is used in shoes mass production and in bespoke shoemaking as well.

Aluminium Last

we use aluminum last in shoe making for shoe sole molding. This kind of lasts are placed in special ovens in high temperature.

Different Types of Shoe Lasts

Depending on the style of shoe that is being made the last will need some special features to allow the shoe to release the last. The standard athletic shoe with a floating lace-up tongue can use a solid last. Loafers, Oxfords, and boots will require a last that can articulate so the shoes are not damaged during the production process.

Solid Shoe last: The most common type of shoe lasts, the solid last can be made of plastic, aluminum, or wood.

|

| Solid Shoe Last |

Hinged Shoe Last: The hinged last is often used for making fine leather shoes. The last can adjust allowing easy removal.  |

| Hinged Last |

Scoop Last: In the scoop last, the instep is removable allowing a cone of the shoe to be shaped.  |

| Scoop Last |

Telescoping Last: Used for high boots, the telescope last separates into parts allowing easy removal.  |

| Telescopic Last |

There are different type of shoe lasts. Why each footwear type must be done on a specific shoe last? Because each shoe type has its own construction and this construction must suit also your feet parameters, that is why we need different lasts for each type. we can make few footwear designs on the same lasts but we can’t make different heel height shoes on the same lasts.

Usually sandals have open construction. It is open in the toe, in the instep and heel part, and most of them have fastening in the ankle area. the pumps are constructed in the way where they sit tightly on your feet and without any fastening. The pump last is always longer than your feet length and have toe allowance at least (not smaller than) 8 mm.You never will find sandals with pointed toe shape ( only if it is some fashion trend). The toe shape of sandal last is similar to the shape of feet toes and doesn’t have many variations. The toe shape of pump last has different variations ( square shape, rounded shape, pointed toe shape etc).

Each "shoe last " is designed for a particular heel height, toe shape, and type of footwear. Many styles of shoes can be made on the same shoe last , but the toe shape and heel height will be the same for each pair made on that shoe last. If you want to have shoes with different toe shapes, then it is necessary to create more than one pair of shoe lasts. A proper fitting pair of shoe lasts is a solid investment, and the first step towards creating proper fitting and fashionable footwear. |

|

|

3 Different Shoes

Made on the same " Shoe Last " |

Notice how each Shoe Last in this collection is designed for a different Heel Height & Profile. Examples :

Top Left = Western Boot

Bottom Right = Flat Moccasin In this picture, each drawer contains a complete size run for that style of shoe last. Traditionally, shoe lasts were made of hardwoods, such as Maple or Beech. Modern day shoe lasts are made of high density plastics, that are 100% recyclable. |

|

|

Craftsmen's Shoe Last Collection |

|

The last is the single most important element in the shoe making process. The last is made from measurements to ensure proper size and fit of the shoe which includes tread and shoe performance. Standard measurements include girth of ball, waist, and instep for given shoe sizes relative to the type of footwear

Measurements - The majority of measurements are volume rather than the traditional length and width associated with shoe fit.

Throat opening - The distance from the vamp point to the back seam tuck.

Throat opening - The distance from the vamp point to the back seam tuck.

Length - The length measurement of the foot from the back of the heel to the tip of the longest toe.

Foot Girth - There are four girth and circumference measurements taken on a last. These are the ball; waist, instep and heel (back of heel to instep). Measurement requires careful assessment of the foot, which cannot be accomplished with the same precision as linear measurements. The modern last maker uses precision instruments to determine girth but the old shoemakers used the hand span to this same effect. Aspects of the foot were measured against the shoemaker's hand; the ball of the foot was compared to the girth between the thumb and the middle finger. The instep was measured between the thumb and the little finger. This method was subject to enormous variations depending upon the size of the shoemaker's hand.

Ball girth - This is the girth measurement around the ball of the last to determine the width and volume allowance inside the shoe.

Waist girth - The girth at the waist on the last.

Instep girth - The circumference around the foot at the instep.

Heel girth - The distance around the foot from the rear base of the heel to the top of the instep.

Recede Toe

This is the part of the last, which projects beyond the tip of the toes forming the rounded contour of the front of the shoe. A tapering recede as in sharp toed shoes increases the overall length of the shoe. In a poorly designed last the recede may encroach on the toes increasing tension on the ends of the toes. This may be referred to as tight lasting.

Heel-to-ball - This dictates the position of the hinge of the forefoot (metatarsal phalangeal joints) and the widest part of the shoe (across the metatarsal heads).

Toe Spring - This describes the elevation of the under surface of the sole at the toe to give a slight rocker effect to the shoe. The amount of toe spring (built into the last) depends on the shoe style, sole thickness and heel height. This is built into the last design and compensates for the stiffness of the footwear and provided a stress free take off into propulsion. The more rigid the soling material the greater the toe spring. Many shoes will also display a slight heel spring.

Tread - This describes the width across the sole under the ball of the last and it should correspond to the dimension of the feet. The tread point on the last represents the bottom forepart just behind the ball and in contact with the base plane.

Flare

This describes the curve or contour of the last. The swing is determined by the position of the forepart when the last is bisected longitudinally forwards from the centre of the heel arc. With inflare lasts there is an inward medial swing to the forepart and most modern shoes are made on an inflare last (banana last) because it is thought shoes are more comfortable. An outflare last describes the opposite with the swing lying to the lateral side of the forepart. Sometimes used in bespoke footwear for infants with diagnosed foot development problems. Straights last describe neither an inflare or outflare preference. The long axis of the last when drawn through the bisection of the heel curve describes two equal longitudinal halves. The normal foot has a straight axis and hence straight lasted shoes can be worn on either foot. Prior to the introduction of machinery to make heeled shoes it was common to have shoe made with a straight flare until the turn of the twentieth century.

Chart showing the main parts of a " Shoe Last "

Chart showing the main parts of a " Shoe Last "

Comments

Post a Comment